Premium Enamel handmade in Austria

There are up to 40 work steps behind every product made of RIESS premium enamel. Each piece is carefully made by hand and is an original.

There are up to 40 work steps behind every product made of RIESS premium enamel. Each piece is carefully made by hand and is an original.

Each of our products is lovingly handcrafted piece by piece by our enamel experts. Small variations in colour and irregularities are typical of this. The enamel is applied by dipping or spraying according to the product.

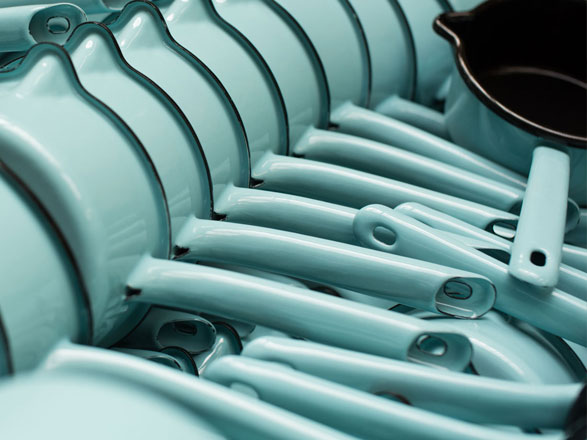

This is located on the reverse side of our hollow handles, at the point where they are attached to the pot. The air escapes here during firing, in all our models with enamel hollow handles.

Our products have two to three layers of enamel (depending on the model): base enamel and coloured cover enamel. As the base enamel leaks out slightly during firing, the thin line called a ‘Seam” – inside the hollow handles where the sides meet.

On the back of our long handles for spout pots, saucepans, etc. the rims around the hanging hole and where the handle is welded to the pot remain open. The iron remains visible here.

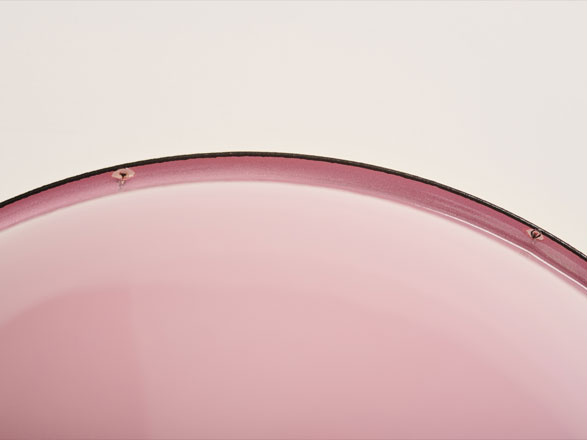

This is where the hook is attached to the rolled rim of the enamel cookware, to hang up the cookware to dry and/or afterwards for firing. A small dot remains here, as the enamel cannot adhere to it.

When “edging” (= milling the forms), a rim develops where the porcelain enamel cannot be fused with the iron. A black line appears where the iron remains visible. Our ladles are an example of this.

For products made of thick iron (aromapot, goose roasting dish), the profile of the mill remains visible at the open rim after the edge is created. The porcelain enamel cannot be bonded with the iron here either.

The feet remain visible on the porcelain enamel under the rim. Here, the pots are placed on rails to dry.

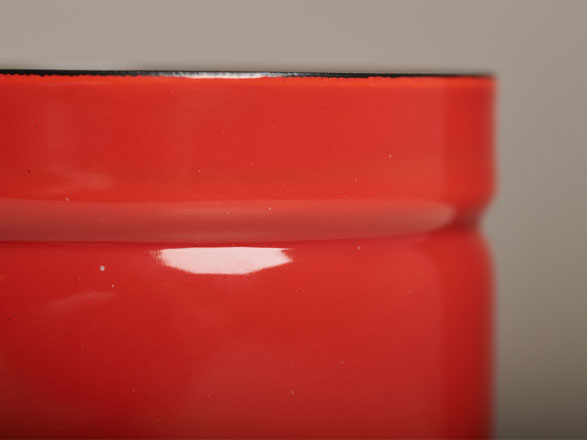

The rim of the blank is curved downwards and around to prevent any sharp edges. Once the porcelain enamel has been applied, the carrier material, iron, remains visible on the underside because the porcelain enamel cannot adhere to the narrow edge. Evenly shaped rolled rims are a real craft in enamelling.

Many of our cooking pots have a protective rim made of metal to provide protection to this exposed part. This is attached after the porcelain enamel is applied. The ends of the metal rim remain visible.

Our seal is applied by hand to the base of each of our products, which certifies our premium quality and that they are handmade in Austria. Only then is the piece a real RIESS product.